Wednesday progress — wiring and caulk

Today’s work was a number of fiddly bits.

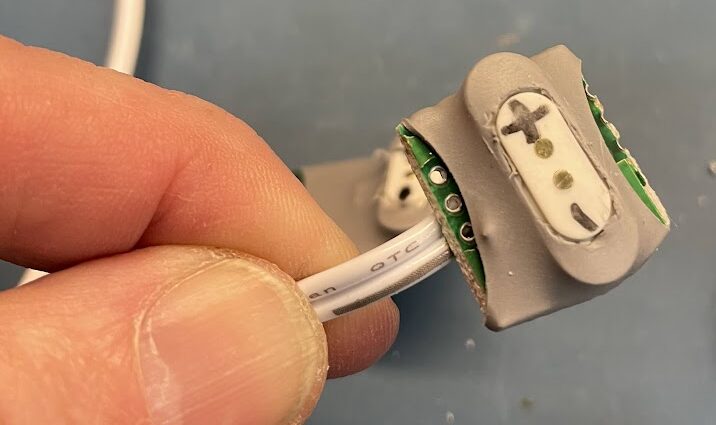

Magnetic Connectors

I bought a half dozen polarized magnetic connectors (only connect one way) that have mating USB-A cables for them, so I can keep battery connections moderately secure but they can break away if the cable snags hard on something. The device-end component, however, has pads on it that are thicker than standard PC board pins, and no easy soldering point son the back. If you wire directly to the back the contact tends to loosen and slide in the plastic, which can make for a poor contact when mated to the USB cable.

They are, however, on the same center spacing as regular pins (0.1″), so I could open up a pair of holes in a scrap of board with useful traces on it and solder them securely there, then solder the wires into another pair.

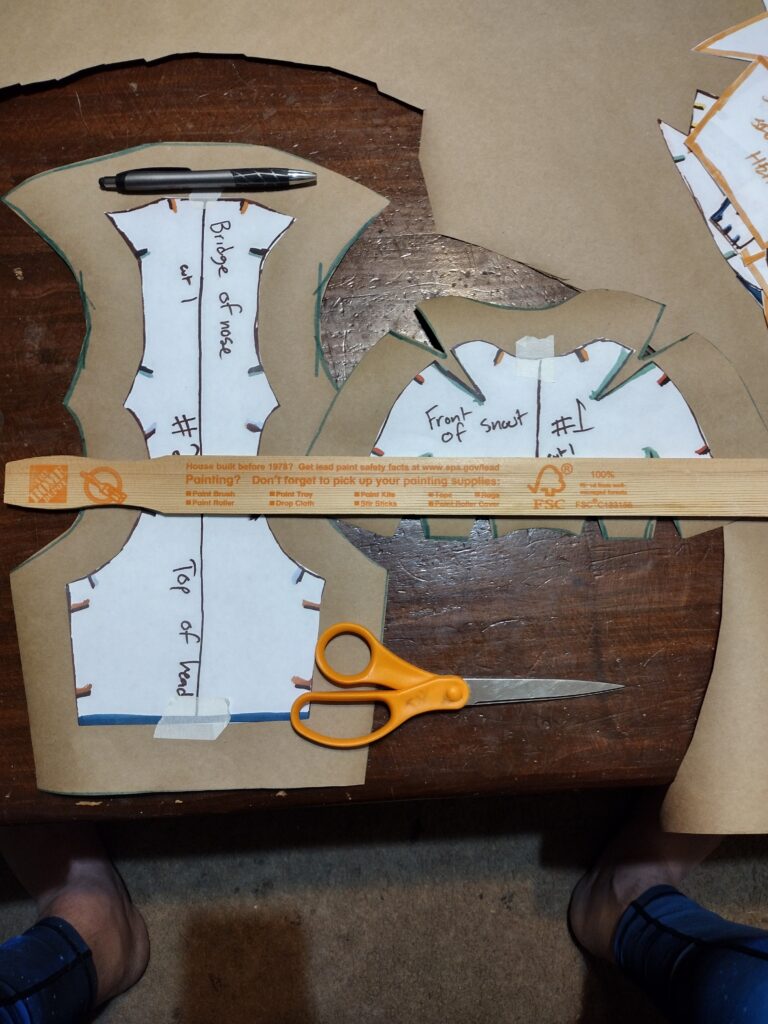

Silicone Caulk Adhesion Test

The gaps in my Identity Disk need to be filled with something, and many cosplayers swear by DAP Kwik Seal. I’m concerned that it might not adhere to the foam and to the silicon tubing on the LED strip, so I did a comparison of Kwik Seal Ultra with GE Silicone Supreme. The GE was a clear winner, with much higher adhesion to the EVA, shorter work time before setting (30 minutes compared to 4 hours), and a good color match.

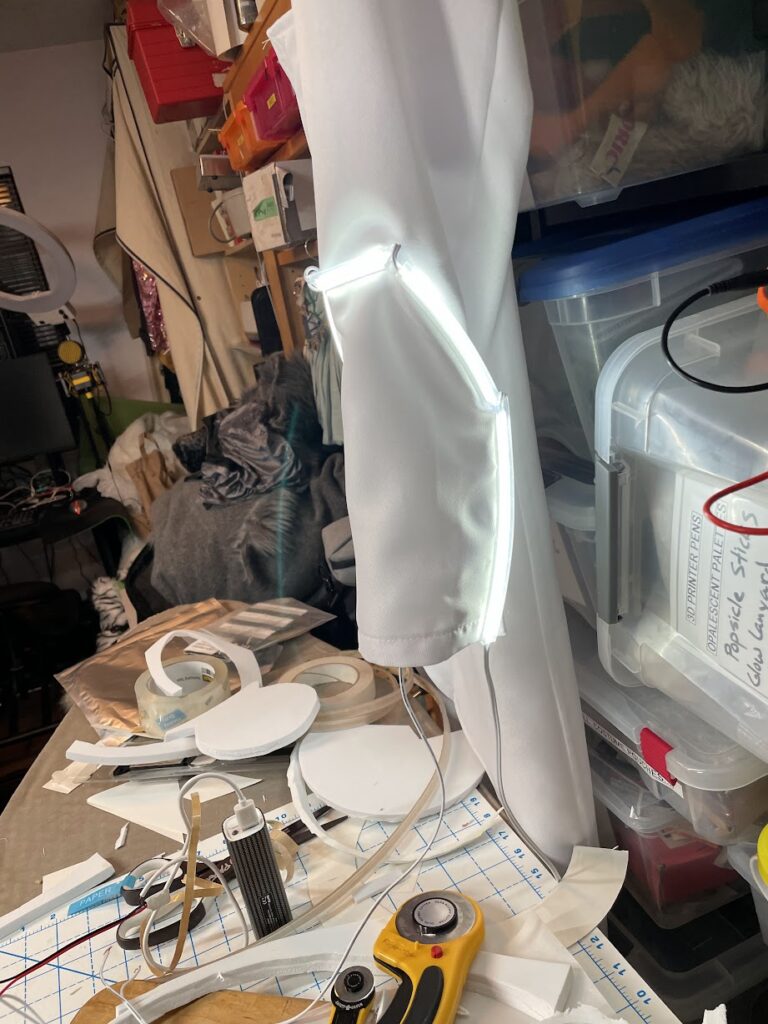

Cuff Adjustment

No new photos for this, but details from old. I noticed the casing for the cuff lighting was hanging weirdly. Examination showed that the last 5 inches of the sleeve were tapered with a stitched-in lap (It’s really remarkable some of the design features hidden in such a cheap coat). As the actual on-screen sleeve is not tapered (it actually looks slightly flared!), I opened those laps, restitched the cuff and the side seam, and shifted the silicon casing. It hangs much better now (and closer to on-screen).